Rongsheng High Quality Refractory Material Gunning Mix for Tundishes

Basic Info.

| Model NO. | Gunning Mix |

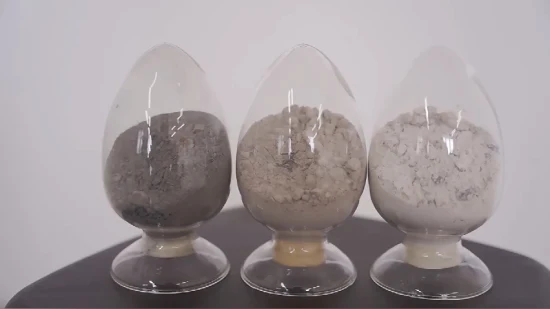

| Shape | Powder |

| Material | Castable |

| Function | Functional Refractories |

| Application | Industrial Furnaces |

| Raw Material | Industrial Alumina Oxide Powder |

| Maximum Service Temperature | 1200-1400 |

| Advantage | High Temperature Resistant |

| Sample | Provide |

| Color | Grey |

| Certificate | ISO9001 |

| Cold Crushing Strength(MPa) | 50~70MPa |

| Product Name | Refractory Material Gunning Mix |

| Transport Package | Bags |

| Specification | 25kg/bag, 50kg/bag |

| Trademark | RSNC |

| Origin | China |

| HS Code | 6902200000 |

| Production Capacity | 80000 Tons Per Year |

Product Description

Rongsheng High Quality Refractory Material Gunning Mix for TundishesProduct Description

Description of Refractory Material Gunning Mix:

The HF series of Gunning Mixes for EAF is based on the construction of the injection material requirements combined with the characteristics of the electric steelmaking process, using high-quality magnesia and special binders, formulated with additives. With attached high, fast sintering, anti-erosion, corrosion and other characteristics. It is the ideal repair material for EAF which can repair weak parts of the lining, making the furnace against corrosion, long use and reduce the consumption of refractory.The main physical and chemical indicators of HF series of Gunning Mixes for EAF

1.High alumina castable.2.low cement refractory castable.3.corundum castable.4.Self flowing refractory castable.5.Corundum mullite castable.6.Silicon carbide castable.7.Zirconia Refractory Castable.8.Lightweight insulation Refractory castable

Features and Advantages of Refractory Material Gunning Mix

1. High refractoriness, High refractoriness under load.2. High density, low porosity.3. Good slag resistance and corrosion resistance.4. High strength and wear resistance.5. Good resistance to flake performance.6. Good thermal shock stability.7. High density and lightweight refractory mixes.8. Installed in large quantities within a short time.9. High adhesion, high density and small rebound losses.10. Minimal dust generation.

Application of Refractory Material Gunning Mix

Used for repair the wall or slag line of eletric arc furnace (E.A.F) or rotary kiln

Refractory Material Gunning Mix Technique Data

| Item | Alumina magnesia castable | Alumina magnesia castable | High alumina castable |

| Application | Work lining | Work lining | Permanent lining |

| Al2O3 %≥ | 60 | 70 | 60 |

| MgO % ≥ | 12 | 10 | / |

| C % | / | / | / |

| Refractoriness ºC≥ | / | / | 1790 |

| RUL ºC ≥ | 1200 | 1350 | / |

| LCR % (1400ºC,2h) | 0~2 | 0~2 | 0~0.3 |

| Apparent porosity % ≤ | 23 | 25 | 18 |

| CCS MPa ≥ | 30 | 30 | 30 |

| Max. working temperature ºC | 1700 |

Production Line of Refractory Castable:

Product Application

Packaging & Shipping

Company Profile

Rongsheng's main products are various types of unshaped refractory products, which are widely used in metallurgy, nonferrous metals, building materials, electric power, petrochemical and other industries. The company has an automatic production line with an annual output of 80,000 tons of intelligent unshaped refractory products. Its products are sold in more than 60 countries around the world and have won wide acclaim from customers.So many customers make business with Rongsheng Refractory.We have no gap in communication.The customers all keep long-term relationships with us.

Certifications

FAQ

Q: Are you trading company or manufacturer ?

A: We are Manufacturer of refrcatory , We can provide you with high quality products at more competitive prices

Q: When can I get the price?

A: We usually quote within 24 hours after getting your detailed requirements, like size, quantity etc. If it is an urgent order, you can call us directly

Q: What about the lead time for mass product?

A: The lead time is based on the quantity, about 7-12days.