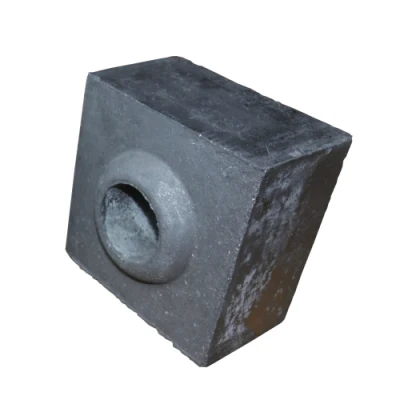

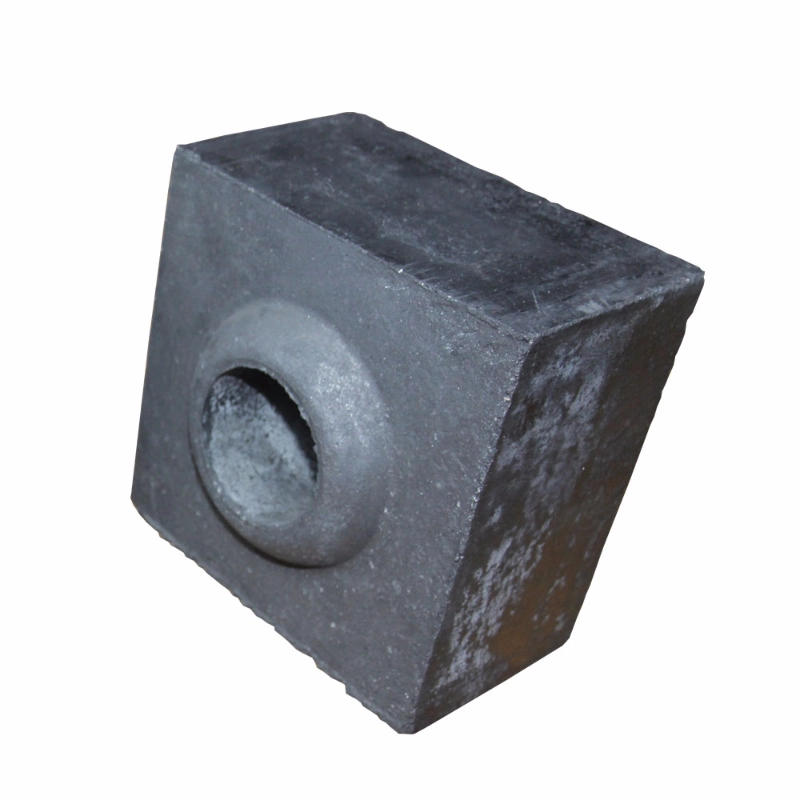

Tundish Refractories Tundish Well Block

Basic Info.

| Model NO. | Tundish Well Block |

| Shape | Block |

| Material | Alumina Block |

| Brand | Semc |

| Material System | Tundish Refractories |

| Product Name | Tundish Well Block |

| Transport Package | Standard |

| Specification | Standard |

| Trademark | SEMC |

| Origin | China |

| HS Code | 69022000 |

| Production Capacity | 5000PCS/Day |

Packaging & Delivery

Package Size 50.00cm * 70.00cm * 40.00cm Package Gross Weight 5000.000kgProduct Description

Tundish Refractories Tundish Well Block

Introduction:

Tundish well block is made of high-quality raw materials, precision-formed, formed by strong pressure, and dried at low temperature. The well block is used in conjunction with nozzle, mainly used for continuous casting tundish.

Advantages:

Tundish well block has high corrosion resistance, good thermal shock resistance and erosion resistance.

Tundish Refractories Long Nozzle

Introduction:

With a special clamping device, the long nozzle is fixed between the ladle and the tundish to isolate the contact between the molten steel and the air to reduce the secondary oxidation of the molten steel, improve the purity of the molten steel, and prevent the steel from splashing.

The use of a non-preheated long nozzle has the advantage that it can be directly installed and used without preheating, thereby saving fuel costs and reducing the labor intensity.

Advantages:

The long nozzle has strong adaptability to steel grade and good corrosion resistance.

Product Description:

NEMA EPACT are three phase induction motors which are single speed, totally enclosed, self-cooled, continuous duty, low voltage and cage type. The motors conform to NEMA MG1 standard and adopt casting iron frames. The efficiency meets America NEMA EPACT standard. Service factor is 1.15. The motors have passed America CC certificate and Canada CSA certificate.

| Product Name | NEMA EPACT Hight Efficiency Three Phase Induction Electric Motor (Design A, B) |

| Frame | 143T~587T; |

| Rated power | 1-500HP,Service factor: 1.1 |

| Rated Voltage | 230/460V,460V or 575V |

| Rated frequency | 60Hz |

| Structure | TEFC (IP54,IP55) |

| Thermal Class | 155 (F) |

| Main Application | AC motors have high efficiency, no smoke, no smell, no pollution to the environment, and less noise. Because of its series of advantages, it is widely used in industrial and agricultural production, transportation, national defense, commercial and household appliances, medical and electrical equipment and other fields. |

Continues Casting Machine with CE certificated

Price and Equipment List for R6m, 3strands, 12meter billets CCM

NO:CCM6312

I.Technical data

1. CCM

Casting radius:R6m

Billet specification:100*100, 130*130, 150*150

Strand number:Strands 3 strands

Dummy bar:Rigid dummy bar

Ladle support:80t ladle turret

Cutting way:Automatic flame cutting machines

Electrical system:Siemens Transducer, Siemens PLC, SCHNEIDER contactors.PLC automatic controlling

Billets Size:6m\12m

Pusher-type:Hydraulic pressure system, Mechanical car type.

2.Water system

A.Mould cooling water

Influent pressure:P≥0.9Mpfa

Influent temperature:≤35C

Influent effluent temperature difference:6-10C

pH:7.5-9

Water total hardness:≤150mg/L

Flow:≥360Nm3/h

B.Secondary cooling water

Hydraulic:P≥0.6Mpa

Impurity particle size:≤0.2mm

Flow:≥80Nm3/h

C.Machinery cooling water

Hydraulic:P≥0.6MPa

Impurity particle size:≤0.5mm

Flow:≥60Nm3/h

3.Gas System

A. Oxygen

Pressure:P≥0.9Mpa

Purity:≥99.5%

Flow:≥4Nm3/min

B. Gas

Pressure:P ≥0.3MPa

Combustion value:≥93700KJ/m3

Flow:≥1.5Nm3/min

C. Compressed air

Pressure:P ≥0.5MPa

Flow:Q≥5Nm3/min

Withdrawal straightening machine

Power:11KW

Rated revolution:1500/min

Billet withdrawing force(max):11000N

Straightening force (max):220000N

Tension speed range:0.3-3.0m/min

Dummy bar speed (max):3.99m/min

4.Central hydraulic station

System pressure:P≥8.0MPa

System flow:Q=37.5L/min

II.Supply cope

1.On-line equipment list

No Equipment name Unit Qty. Remark

1 Ladle turret PC 1 100t capacity for each arm

2 Tundish moving car PCS 2

3 Tundish PCS 2

4 130sq.Mm mould PCS 3

5 Mould cover SETS 3

6 Oscillation device SETS 3

7 Secondary cooling manifold(stainless steel) and support SETS 3

8 Guide section for secondary cooling SETS 3

9 Steam drainage system in the secondary cooling system SET 1

10 Withdrawal straightening machine SETS 3

11 Dummy bar PCS 3

12 120sq Dummy head and transition head SETS 3

13 Dummy bar guide wheel SETS 3

14 Dummy bar storage device SETS 3

15 Dummy bar heat protetion cover PCS 3

16 Roller table before cutting Group 3

17 Transmit roller table Group 3

18 Discharge roller table Group 3

19 Transverse pusher SET 1

20 Cooling bed SET 1 Step by step

21 Overflow chute PCS 6

22 Hydraulic station system SET 1

23 Cooling water distribution system SETS 3

24 Electrical system SETS 3

A Power supply conbinet SET 1

B Frequency conbinet SETS 3

C PCL conbinet SET 1

D Main operating table SET 1

E Suspension operating box SETS 3

F Small operating box SETS 3

27 Steel structure platform Batch 1

A Main operating platform

B Temperature test platform

C Dummy bar storage platform

2\Auxiliary equipment

No. Equipment name Unit Qty. Remark

1 Water pipe, connector valve.etc Batch 1

2 Various cable, tube.etc Batch 1

3 Drainage gun PCS 3

4 Cutting gun PCS 3

2. Price:USD FOB Shanghai.

3. Lead time;100 days

4. 30% advance payment, 30% payment 20 days after first payment, 40% payment

Paid before date of shipment.Management Installation:(we consider send 3 engineers to your factory), ACCOMMODATION AND TRANSPORTATION COSTS will be paid by buyer.Totally overse charges paid by buer.

The buyer shall compensate the experts at USD 150 per day for delaying time per engineer.The seller should be responsible for the scene testing;After normal melting the seller should be responsible to guarantee repair or change of the faulty components in 6 months

Delivery by 1 piece frame container, 1 piece 40HQ container, 5 pieces 40GP container.

.

dust removal equipment water bath dedusting equipment

Features of electric furnace dust removal system:

1) Dust removal system equipment has strong reliability, not affecting the normal operation of smelting, easy for maintenance.

2) Gas flue capture mode belongs to the whole process of capturing.

3) Gas flue capture rate is more than 98 percent, can achieve plant roof, can not see smoke

4) Dust collection efficiency is more than 99 percent

5) Dust concentration in the workshop is less than 10mg/m3.

6) Low cost for long-term operating , stable efficiency

7) The wind engine noise is less than 80dB.

8) The flue has no dust fouling phenomenon

9) Dust collecting volume is more than 12Kg / t steel

Induction furnace is used for smelting or insulating ferrous metals, non-ferrous metals, sponge iron, such as scrap iron, scrap steel, copper, aluminum and so on. Complete working equipment such as continuous casting machine, rolling mill, mainly used for the production of billet, steel bar, angle steel, H-beam, I-beam, etc. Using KGPS, IGBT, single or double power supply technology, PLC (Siemens) can be realized throughout the monitoring.

Main supply list: 2 sets of electric furnace body, 2 sets of hydraulic or mechanical tilting electric furnace mechanism, 1 set of control platform, 1 set of intermediate frequency control cabinet (6 pulse 1, 12 pulse 2, 24 pulse 4), low voltage control cabinet (6 pulse 1, 12 pulse 2, 24 pulse 4), 1 set of capacitor cabinet, 4 or 8 water-cooled cables; 1 water temperature alarm, 1 leakage alarm; 1 crucible mold, 1 liquid One batch of pressure steel pipe, one set of copper row, three water tanks. Transformer, cooling tower, furnace builder, furnace lining ejector, furnace cover.

Product Model: GW1.5-IGBT-1300-0.5-B

Dual output with a set of power supply, can supply power to two sets of furnaces simultaneously, to achieve "one for two", total power can realize stepless free distribution on two sets of furnaces. Equipping two sets of furnaces, one is used for melting or heating refining , the other is used for insulation and casting, and two sets of furnaces can mutual replace to use. Medium frequency power supply device of IGBT transistor module can be used for melting, induction heating, heating treatment.

Main Technical Parameters

| No. | Item | Technical Parameters |

| 01 | Furnace rated capacity (steel) | 1.5t |

| 02 | Rated power of medium frequency power supply (1000+300) | 1300kW |

| 03 | Maximum power of single furnace output | 1000kW |

| 04 | Rated frequency | 500Hz |

| 05 | Working temperature | 1600ºC |

| 06 | Melting rate(Rated loading material, concentrate, density, the third furnace, auxiliary time not counting) | 1.6t/h |

| 07 | Power consumption(Rated loading material, concentrate, density, the third furnace, auxiliary time not counting) | 600kWh/t |

| 08 | Cooling water consumption- medium frequency power supply cabinet | 30m3/h |

Supply Range of Complete Set

| No. | Item | Unit |

| 01 | IGBT-1300(1000+300)-0.5-B medium frequency power supply device of transistor module | 1set |

| 02 | "Medium frequency power supply cabinet using closed cycle water cooling device"(Set in the rectifier cabinet) | 1set |

| 03 | Air conditioning refrigeration equipment (Set in frequency power supply device) | 4 sets |

| 04 | GW1.5t Melting Furnace | 2 sets |

| 05 | Hydraulic actuator(including hydraulic pump station, console, hydraulic oil tubing) | 1set |

| 06 | Water-cooled cable | 8sets |

| 07 | Cooling water dispenser(used for inductor and water-cooled cable) | 2 sets |

IGBT Dual track working GW1.5-IGBT-1300-0.5-B

IGBT technology b GW3-IGBT-2000-0.2-B

furnace with cover GW1-IGBT-800-1-B

KGP-7t-5000-dual

We provide PS steel chip crusher 2018

PS series steel chip crusher, used to crush all kinds of car scraps, shavings and cuttings into 20-50mm scraps, in order to enter the chip and machine (metal chip briquetting machine) for briquetting treatment.

[Features]

1 Hydraulic system is adopted to effectively solve the overload protection problem;

2 Hydraulic motor, high torque, saving power;

3 PLC control.

Version:0.9 StartHTML:0000000105 EndHTML:0000011308 StartFragment:0000000141 EndFragment:0000011268List of 450 heavy scrap crusher Serial number Name Specifications (mm) Qty Remarks 1 Crusher shell 50mm 1 set Q235, plate thickness 50mm 2 Host hammer High manganese steel 1 set 16 pieces, each hammer head 80kg 3 Circular cutter High manganese steel 1 set 16 pieces, 45kg for each round cutter 4 Rotor disc φ1100 1 set Outer wear electrode welding 5 Spindle Diameter 390mm 1 root 6 Sieve plate φ65×100 1 set Steel casting ZG45 7 Motor 220KW 2 sets 8 Starting cabinet Soft start 1 set Control equipment operation 9 Hydraulic pumping station Matching 1 set Unpacking cylinder, movable plate cylinder, Forced feed cylinder 10 Dust removal system Matching 1 set Cyclone dedusting, pulse dedusting 11 Feeding machine 1 set 12 Magnetic separator 1 set 13 Loader heavy conveyor 1400×12000 1 set 14 Discharge belt conveyor 1000×10000 1 set 15 Belt conveyor 1000×8000 1 set 16 Waste belt conveyor 800×6000 1 set 1.Product principle and Application The crushing production line uses the principle of hammering. Under the drive of a high-speedand high-torque motor, the hammers on the host rotor take turns to hit the objects to be crushed in the cavity. Through the space formed between the liner and the hammers, After the crushed object is torn into a crushed object conforming to the specifications, a high-quality crushed material with high purity can be obtained under the action of a magnetic device. This production line is used to process waste car body, tinplate, household appliances, bicycles, empty cans and other lower scraps to make it into a superior steel making raw material. The machine continuously crushes, removes the coating film, increases the specific gravity of the volume, prevents the electric furnace from exploding, and improves the water output rate under certain conditions. 2.Technical conditions 1.1 (1) Ambient temperature: -20 ºC -40 ºC (2) Production staff: 3-5 people (3) Installation method: According to the installation diagram, the technicians guide the installation 1.2 Power supply (1) Three-phase four-wire 380V AC (±10%), 50HZ (±2%) (2) Low-voltage power supply of the equipment: 380v / 50hz; Working lighting power: 220v / 50hz; 3.Processing object 1. Waste car body (excluding engine, reduction gear box, tire, etc.); The 450KW crushing line needs to be broken into squares not larger than 800mm * 800mm when crushing colored steel tiles. 2, Tinplate (cans, etc.) 3. Iron sheet for home appliances (excluding motors, compressors, shafts, etc.) 4. ≤6mm light and thin materials and similar domestic waste 25, Empty cans (wash out thin materials, coatings, etc.), non-sealed cans. Note: After all the processed materials have been preliminarily processed, the shape and volume need to ensure that they can smoothly enter the main machine inlet. (Such as cans, small paint buckets, color steel tiles, car shells, etc.) 4.Not suitable for broken objects 1 Dangerous things: a Sealed container, conduit, etc .; b. Items that may cause an outbreak, fire, etc .; 2 Scrap cars: a. Subjects other than passenger cars; b. Engine, converter, differential gear, tire;