Quaternary Cyanide

The price is to be adjusted by negotiation for large orders. INTRODUCTION Simple operation, both rack plating and barrel

Basic Info.

| Model NO. | RC-NCY |

Product Description

The price is to be adjusted by negotiation for large orders.

INTRODUCTION

- Simple operation, both rack plating and barrel plating are applicable.

- Do not contain cyanide.

- A dense and uniform thin film of quaternary metal zincate can be produced on the surface of aluminum, which provides a good adhesion for direct copper plating, nickel plating, tin plating and chemical nickel deposition in the subsequent process.

SOLUTION MANTENANCE

The replenishment of cyanide-free zincate solution for aluminum can be calculated according to the specific gravity. The specific gravity unit is about 1.10 when the solution concentration is 250 ml/l, therefore, the specific gravity of the solution should be maintained between 1.08 and 1.12. 20 ml/l cyanide-free zincate solution should be added for each increase of 0.01 specific gravity unit.

1 g/l of the zinc level will be provided when 22 ml/l of the cyanide-free zincate solution is added.

DETERMINATION OF ZINC LEVELS

- Pipette a 1 ml sample into a Erlenmeyer flask.

- Add 80 ml of pure water.

- Add 5 ml of 20% (v/v) triethanolamine, also 1 g of ammonium fluoride.

- Add 10 ml pH = 10 buffer and 10 ml ethanol.

- Add 3-4 drops of PAN indicator.

- Titrate with 0.1M ETDA until the solution changes from red to yellow as the end point.

EQUIPMENT

Tank: PP, PVC, or high-density PE

Rack: PP, PVC, or 316 stainless steel

Air agitation: appropriate and even stirring is not required

Circulation: 3 to 4 times

Filtration: continuous filtering is required

Ventilation: required

Cooling system: required

Heat system: required

SAFETY AND ENVIRONMENTAL

A Material Safety Data Sheet (MSDS) includes product safety instructions and environmental protection instructions. Read and review the MSDS for appropriate health and safety warning before use.

WARRANTY

- We provide guarantee for product quality under the valid law.

- The quality of the product after reprocessing or repackaging by customer is not included in the guarantee.

- Please feel free to contact us if you have any questions or issues about the products, we are ready to answer at any time.

COLOR & PACKAGING

This product is a yellow-green liquid with plastic drum packaging. The packaging specification is 25 kg/pcs.

MPORTANT NOTICE REGARDING THIS INSTRUCTION BOOK

The product information and recommendations contained in this document are based on our experimental theory and data. Due to the particularity of the surface processing, further as the actual use of our products by others is beyond our control, NO GUARANTEE of any kind is made as to the effects of such use, and NO RESPONSIBLE for any consequences. Also, all the information in this document cannot be used as evidence of copyright infringement.

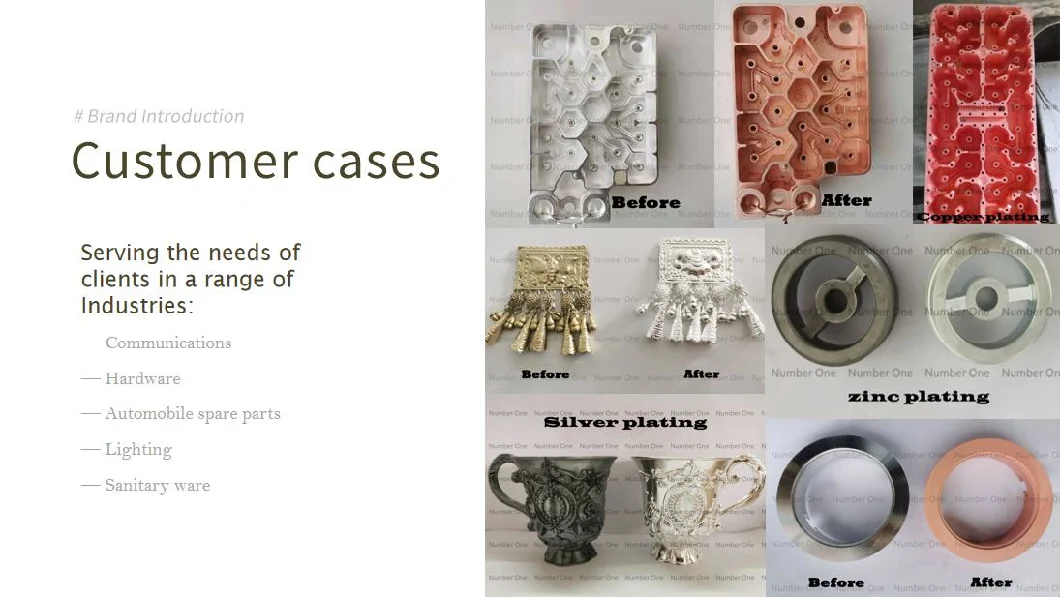

COMPANY PROFILE

Foshan Nanbowang Environmental Protection Technology Co., Ltd is a subsidiary of Foshan Renchang Technology Co., Ltd., with more than 10 years experience of environmental metal finishing, R & D and sales, and has won a national high-tech enterprise. Our company is mainly engaged in the research and development of environmentally friendly electroplating additives and is committed to the development of cyanide-free, phosphorus-free and ammonia-free metal finishing technologies.The mission of is 'Innovation, Environmental, and Development'. The company's technical team has participated in a number of high-tech research and development, and has independently developed and obtained 3 nationally authorized invention patents and 3 copyrights.

At No.1, we offer high-caliber electroplating additives to improve the appearance and performance characteristics of your components, and have continually refined and evolved our electroplating additives to meet 21st century quality standards. We are agile, efficient, and committed to providing 100% customer satisfaction.

Send to us